Clean Engine Sludge in 2 hours.

BG Dynamic Engine Restoration Service is a one-of-a-kind service that can help you fix even the most difficult engine oil sludge problem in just two hours. Read this article to understand the engine oil sludge formation process.

Engine oil sludging has become a nasty headache for mechanical workshops throughout Australia. This article will help you understand how you can provide a cleaning service in such a situation. We will also help you understand why it happened in the first place and how you can prevent that.

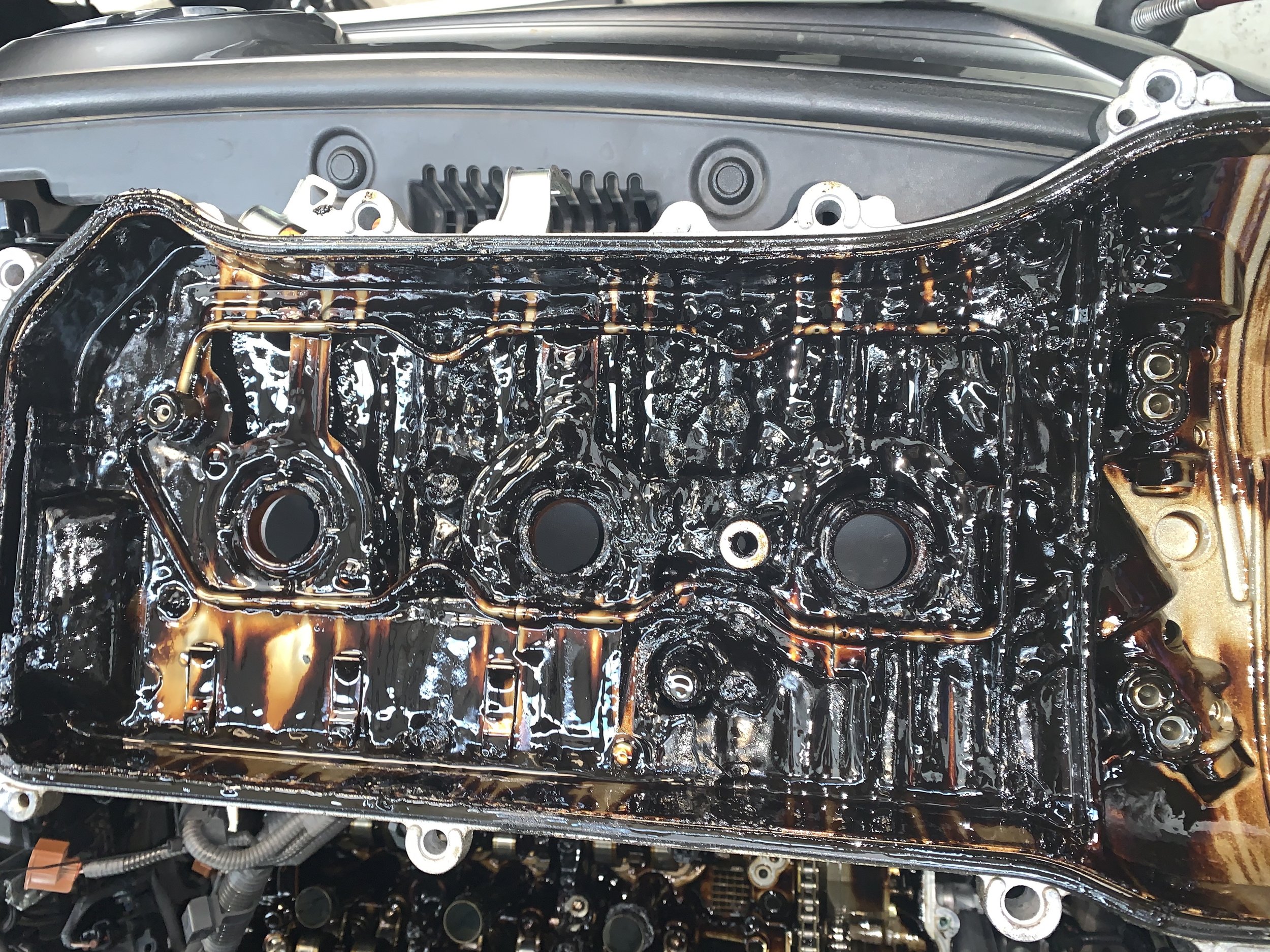

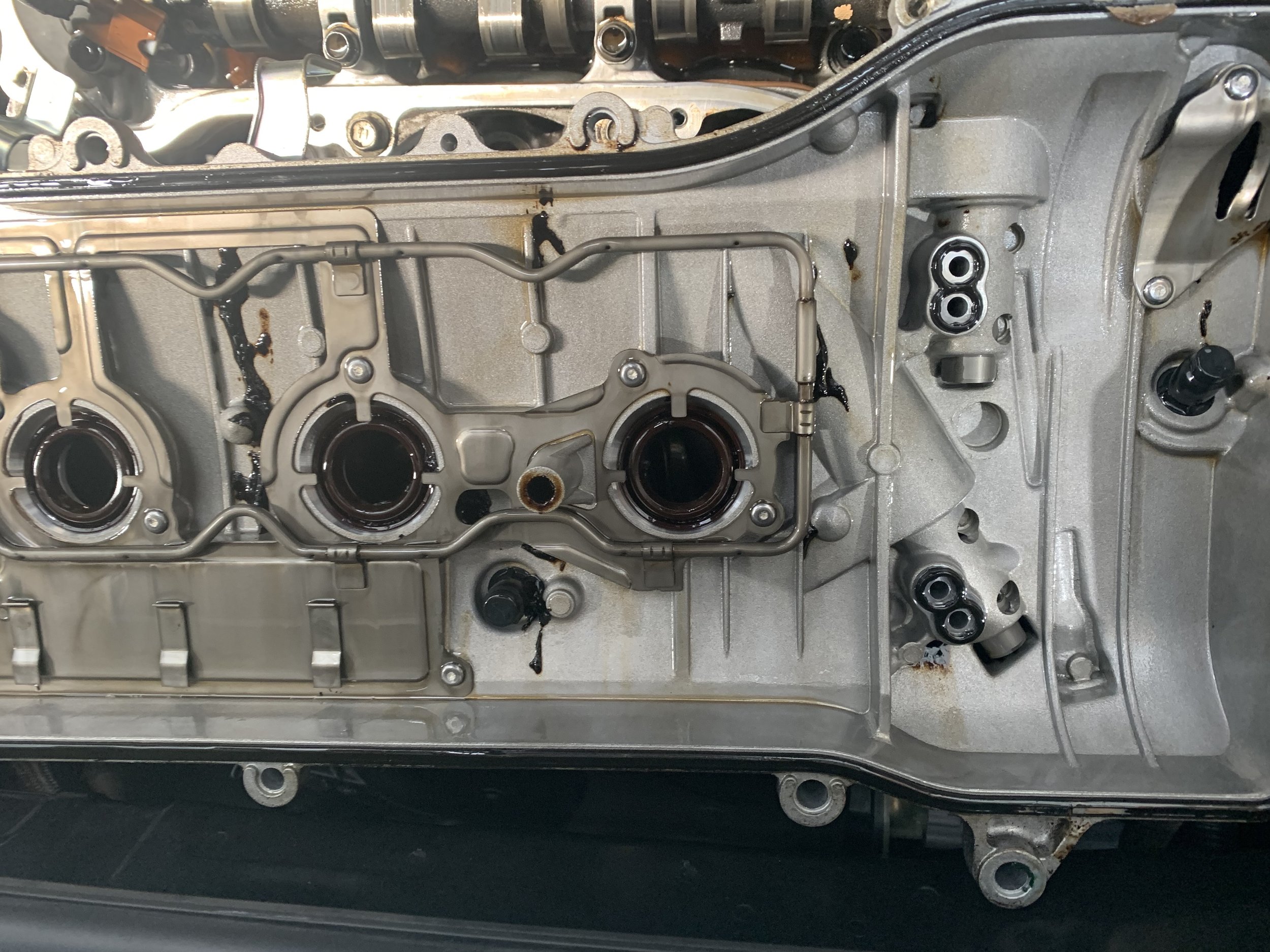

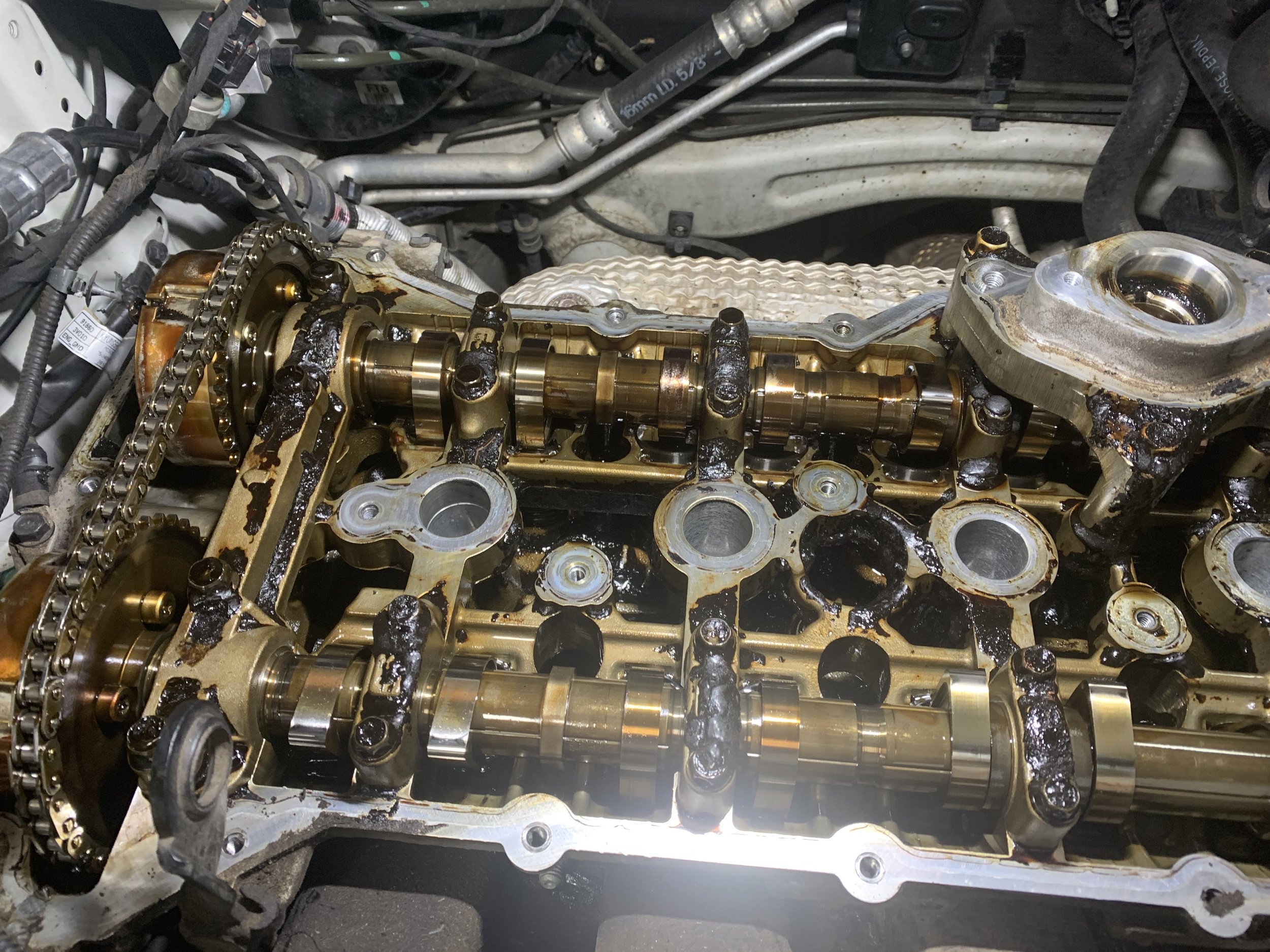

When my father owned his mechanical workshop, there were times; he encountered a customer with a sludge-filled engine. The circumstances behind the problem were a bit varied but always contained several potential issues. The most common issues were poor service history, either missed services or extended service intervals. At times you would see severe contamination of coolant or fuel. Component failures on connected systems such as cooling systems and fuel/air were also quite common.

Sometimes, but less common, we would notice the usage of incorrect engine oil (viscosity/quality), mechanical modifications (performance hardware/tuning and now and then just pure neglect or misuse.

It was never comfortable to explain the finding of a sludgy situation to the customer. In most cases, they wanted the vehicle repaired to a useable state. To which our family’s workshop suggested a few options that many others also offer to this day:

Replace the engine

Manually Clean the Engine

Sell the Vehicle

Service the engine multiple times (and say a few prayers)

Options are great for workshops providing services to customers. However, all these options are pretty costly either in time, finances, or a combination of both. An option only recently available to Australian workshops could solve such sludgy issues while minimising time and financial requirements.

Dynamic Service Origin

The BG Dynamic Service was originally developed in collaboration with Volkswagen for the North American market in 2007. Changes in engine technology such as smaller sump capacities, turbocharging, and extended service intervals encouraged the rapid formation of sludge build-up. Some vehicles experienced the phenomenon in as little as 20,000 miles / 32,000 kilometres. Technicians at dealerships and independent workshops alike could clean up the sludge-filled engines with the service BG provided. This provided a successful alternative to expensive engine replacement options or time-consuming manual cleaning methods.

For additional insight, see TB2013233

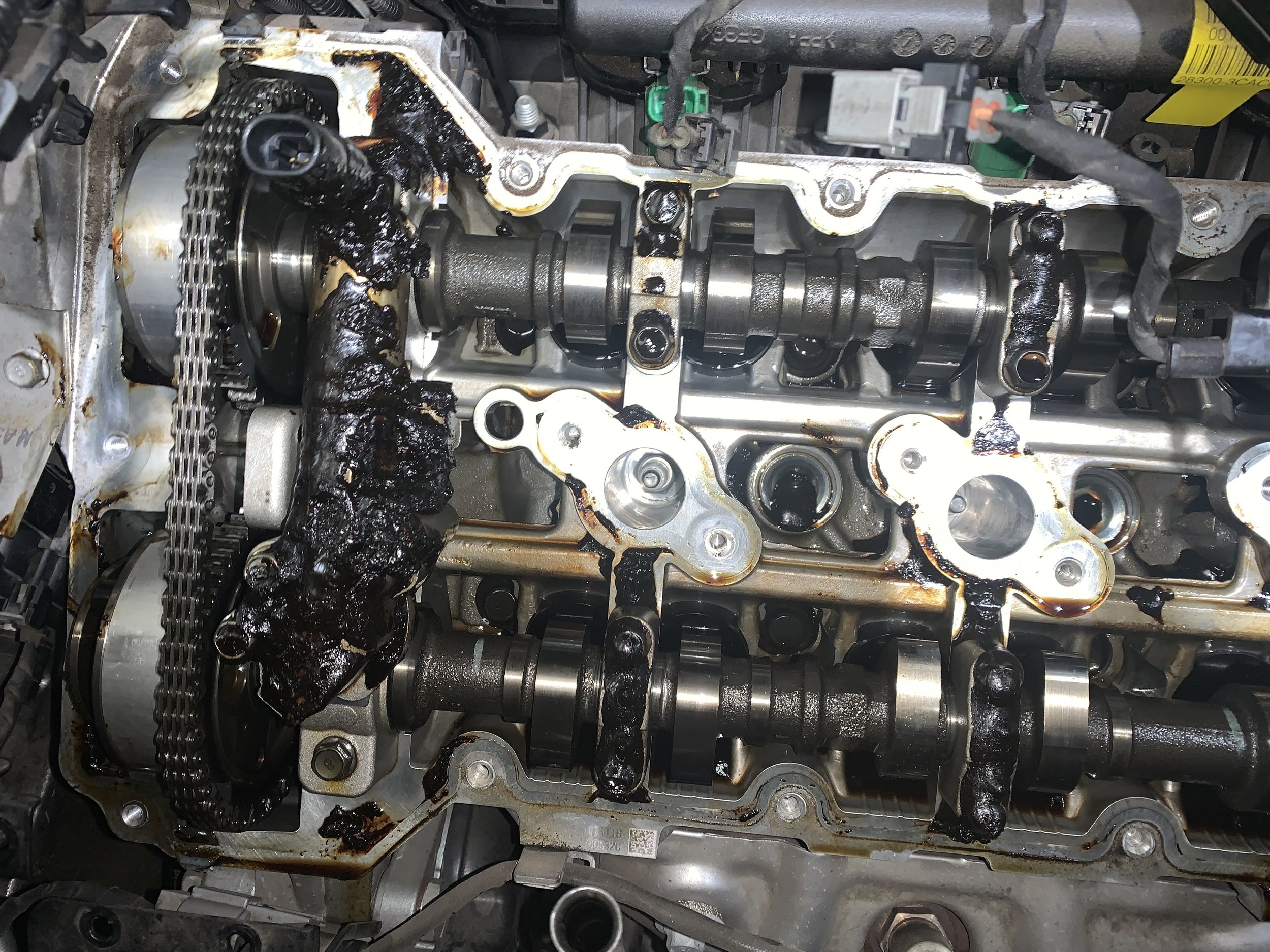

After solving a potential catastrophe in-warranty repairs for Volkswagen (an estimated 4.4-million-dollars), the BG Dynamic Service became forgotten. Improvements in oil technology and rationalized service intervals helped alleviate the short-term problem. Lately, new standardized engine technologies have placed additional load on engine oil, such as hydraulic belt tensioners, lifters, and timing components. Many manufacturers have again reduced the engine oil capacity while incorporating smaller filters, multiple turbochargers, and extended service intervals. These changes have again increased the probability of oil sludge formation as a common occurrence in today’s workshops. The BG Dynamic Service has been needed to rescue sludge-filled engines more than ever.

BG Dynamic Engine Restoration Service Today

From the early days, we have tweaked the use of BG Dynamic Engine Cleaner and the whole service process. Nowadays this service is also available for diesel engines. There are specific instructions to this service, and they need to be followed by the letter. The Process in short for petrol engines:

At the start of the service, we drain the crankcase empty and change the new oil filter. Then we fill the whole crankcase with BG Dynamic Engine Cleaner and BG Platinum® 44K® to the fuel tank. We then run the engine for 45 minutes, with 3000 rpm. During this process, we monitor oil pressure.

After the first 45 minutes, we stop the engine and drain the BG Dynamic cleaner and change an oil filter. Then we fill the crankcase with BG Rinse oil. We run the BG Rinse Oil for 20 minutes with 3000 rpm.

After 20 minutes of rinsing, we drain the crankcase for the last time and change the oil filter. We finish the service by adding new engine oil together with BG Advanced Formula MOA®.

Cause & Effect

The formation of engine oil sludge is an inherent force of nature and can be attributed to several key factors mentioned earlier. It is a process that can be slowed or sped up depending on the environment the oil rests in but is very difficult to stop altogether—referred to as “oxidation”, the breakdown of engine oil is a chemical reaction with the very air that our lungs and engines breathe. The probability of sludge formation within the auto-oxidation cycle increases exponentially with both time and temperature. While there are specific standardised tests for engine oil deposit formation, the environmental factors outside of laboratory settings tend to produce catastrophic results.

The auto-oxidation cycle illustrates the chemical reactions to break down engine oil. Chemical components such as antioxidants in engine oil additives help interrupt the cycle at specific points.

For a basic to complex understanding of oxidation and the auto-oxidation cycle, I highly recommend the following video from Lubrication Explained. For each complete cycle of each loop, three reactive oxidized intermediates (potential sludge) are produced from a single initially formed intermediate.

Essentially the process speeds up and drives itself toward destruction as the following increase in magnitude:

Heat/Shearing/Acid

Water/alcohol Content

Reactive intermediates

The process can be slowed by minimizing the reactions that take place in the cycle:

Keep oil flow high and reduce heat

Reduce entrained air in the lubricant system

Prevent excessive acid formation from fuel dilution

Use antioxidants to bind reactive intermediates instead of oxygen

The catastrophic cases of oil sludging are the effect of letting the auto-oxidation cycle run unhindered. Excessive acidic by-products from fuel, coolant/water entrainment, or depletion of the antioxidant additive package in the oil put the cycle in overdrive. Leaking/dirty injectors failed oil-coolers/head gaskets, and neglected services are quite often followed by rapid sludge formation.

We should look for signs of oil degradation by-products in each service interval. In petrol engines, the typical by-product is varnish. This is often the precursor to sludge and indicates that the service interval is not ideal. The engine oil additive package struggles to keep the oxidation cycle in check.

Prevention is the cure

The BG Performance Service is designed to help protect the engine and fuel systems. It will keep the engine in close new condition with proper servicing.

Regular oil system cleaning will help keep leftover varnish and sludge particles to a minimum. A clean oil system leaves few intermediates to drive the auto-oxidation cycle and allows the proper flow to effectively transfer excessive heat to cool down the engine. BG EPR® Engine Performance Restoration® is ideal for removing potential sludge by-products and varnish leftover after the service interval. With regular use of BG EPR, you will notice a red coloured old oil. That red colour is varnish and other degraded oil by-products removed from the engine.

BG Advanced Formula MOA® is designed to enhance engine oil to fortify it against oxidation and acid formation. Protecting engine oil against Australian high sulphur fuel and Australian weather conditions is vital for vehicle maintenance in our unique conditions. Together with good quality oil, BG MOA can neutralise free radical intermediates that can kill your engine oil.

BG Performance Service is completed with the use of a true fuel system cleaner BG Platinum® 44K®. This complete fuel system cleaner will provide unmatched cleaning power to restore fuel system cleanliness. It will also assist in keeping the fuel system cleaner until the next service. A clean injection system minimises the potential for excessive fuel dilution in the engine oil, one of the driving factors in sludge production.

-Clinton J. Meyer

ACS Certified Petroleum Chemist working for BG Australia.

BG Products Inc.

BG Products, Inc., the leading manufacturer and supplier of automotive fuel and oil conditioners, specialty chemicals, greases, tools and equipment, is ISO 9001, 14001, 17025 and 45001 certified.

As an ISO Certified company, BG Products, Inc. is obligated to provide transparent and factual information. All products are tested and proven to provide added benefits to equipment owners.

If you want to learn more about our products and services you can contact us here.