Under pressure: Low tension piston rings

In order to reduce frictional drag, energy loss and increase fuel efficiency, petrol direct injection (GDI) engines use thinner and lighter piston rings, called low-tension piston rings. Piston ring spring force in older port fuel injection (PFI) engines used to be as high as 30 psi. New PFI and GDI engines can have more than 60 percent reduction in sealing pressure on the cylinder walls.

At the same time, new PFI and GDI engine compression ratios have increased from 9:1 to as high as 14:1. These higher compression ratios dramatically increase cylinder compression and the overall pressure for fuel ignition, sometimes as high as 2000 psi.

All modern engines use low tension piston rings.

Increased upper cylinder contamination, and excessive oil use.

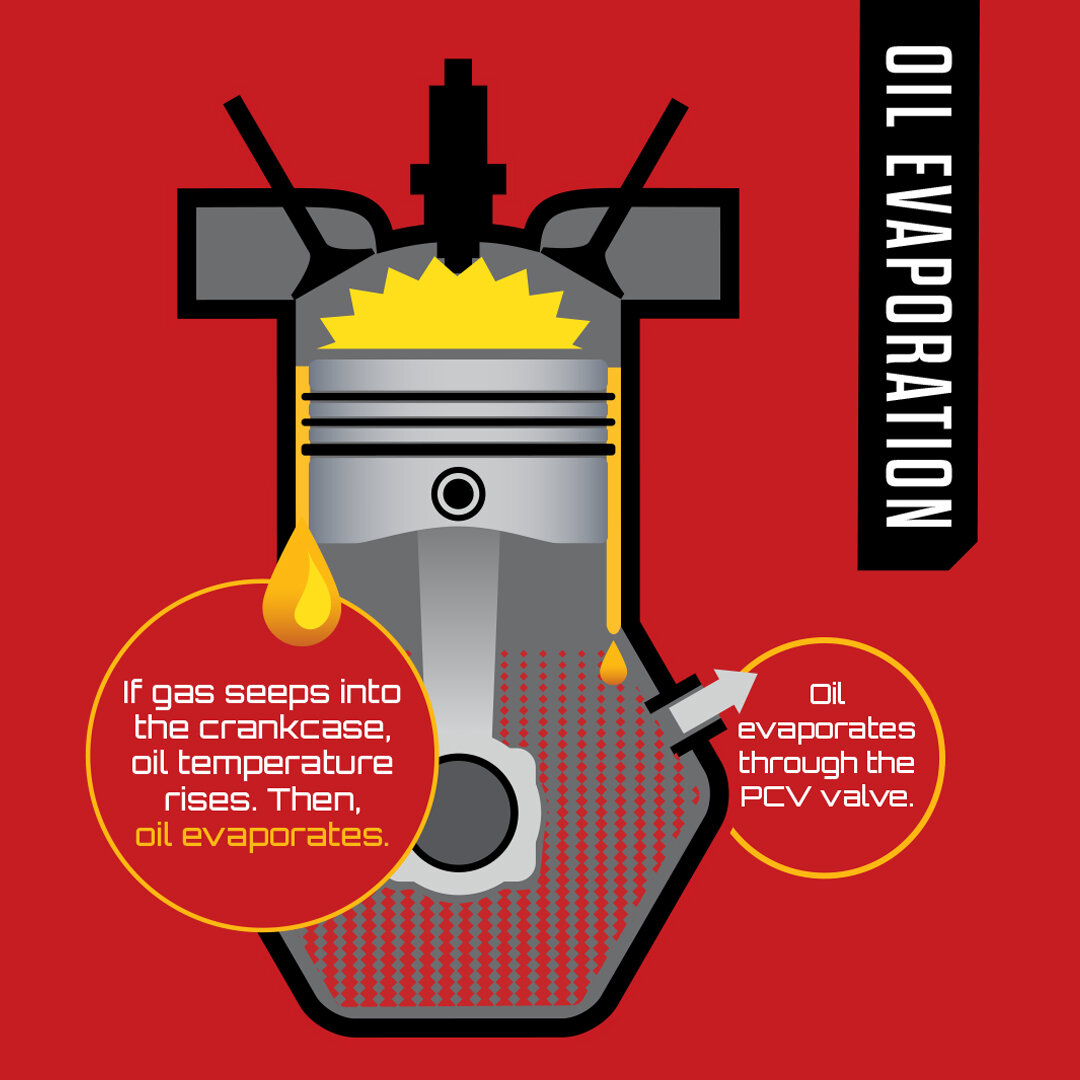

This huge increase in pressure creates more force on the low-tension rings. Piston rings are supposed to prevent fuel and combustion gases from “blowing down” between the piston and cylinder wall, and oil from moving up into the combustion chamber. But, low-tension piston rings have a greater tendency to allow blow-by.

So, not only do you have sludgy, contaminated oil lubricating the rings; but also, because the low tension piston rings have such low spring force, they are less capable of pushing back against the deposits that may form around them. Eventually deposits will impede the rings outward expansion to seal the cylinder wall, which will allow even more fuel and combustion gasses to enter the crankcase. Or, vice versa, stuck rings can promote oil consumption and intake deposit formation due to engine oil moving up into the cylinder and into the intake.

So, while new PFI and GDI engines are known for efficiency, the constant struggle between low-tension piston rings and high operating pressures will eventually erode fuel efficiency, diminish horsepower and contribute to excessive oil consumption.

They quickly lose their ability to properly seal combustion chamber.

Maintenance solution

EPR® Engine Performance Restoration® is essential to clean low-tension piston rings free of deposits, which will keep them from sticking. Immobilized rings cause loss of power, diminished fuel economy and excessive oil consumption. By cleaning piston rings, compression is maximised.

BG Advanced Formula MOA® and BG DOC® Diesel Oil Conditioner are products to protect premature engine oil brake down related to piston ring deposit formation.

Use at every oil change to help prevent problems caused by low-tension piston rings under extreme pressure. BG EPR® is part of BG Performance Service which is more sophisticated service to prevent engine oil breakdown and provide service level cleaning part of regular oil change.

Designed for use on all petrol and diesel engine vehicles.

BG Products Inc.

BG Products, Inc., the leading manufacturer and supplier of automotive fuel and oil conditioners, specialty chemicals, greases, tools and equipment, is ISO 9001, 14001, 17025 and 45001 certified.

As an ISO Certified company, BG Products, Inc. is obligated to provide transparent and factual information. All products are tested and proven to provide added benefits to equipment owners.

If you want to learn more about our products and services you can contact us here.